Aerospace-Grade Luxury Real Carbon Material Accessories

by

Even He

05 Jan 2024

Introduction

Real Carbon Fiber is an advanced material known for its unique performance and aesthetic characteristics, making it an ideal choice for high-end automobiles, aircraft, and sporting goods.Due to the highly technical and craftsmanship-intensive nature of the manufacturing process for real carbon fiber products, production typically takes place in specialized factories to ensure compliance with high-quality standards. The precise execution of these steps ensures the quality, strength, and appearance of the final product.

The typical production steps include:

Cutting Carbon Fiber Cloth: The manufacturing process begins with the cutting of carbon fiber cloth, composed of high-strength carbon fibers.Resin Infusion: The cut carbon fiber cloth undergoes resin infusion to enhance its strength and hardness, providing corrosion resistance for the final product. This step ensures a strong bond between carbon fiber and resin, forming a robust composite material.

Layering and Mold Shaping: Resin-infused carbon fiber cloth layers are stacked together and placed into a mold, determining the final product's shape and structure. The mold can be customized according to design requirements, ensuring product precision.

Baking and Curing: The stacked carbon fiber cloth inside the mold undergoes a baking and curing process to achieve the desired hardness and strength. This curing process involves controlling temperature and time to facilitate complete resin curing.

Coating and Polishing: The final carbon fiber product may undergo coating to enhance its appearance, followed by polishing to achieve a smooth surface. This step helps highlight the unique texture and aesthetic appeal of carbon fiber.

Press Molding

Features:

Lightweight and High Strength: Real Carbon Fiber is renowned for its exceptional lightweight properties and high strength. Compared to traditional ABS materials, real carbon fiber is lighter at higher strengths.

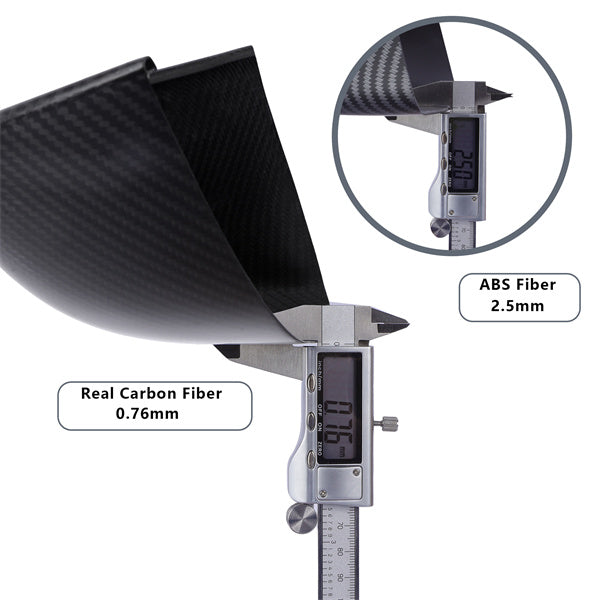

Thinner: The thinner advantage of accessories made with real carbon material lies in their reduced thickness, offering a sleek and lightweight design without compromising strength or durability.

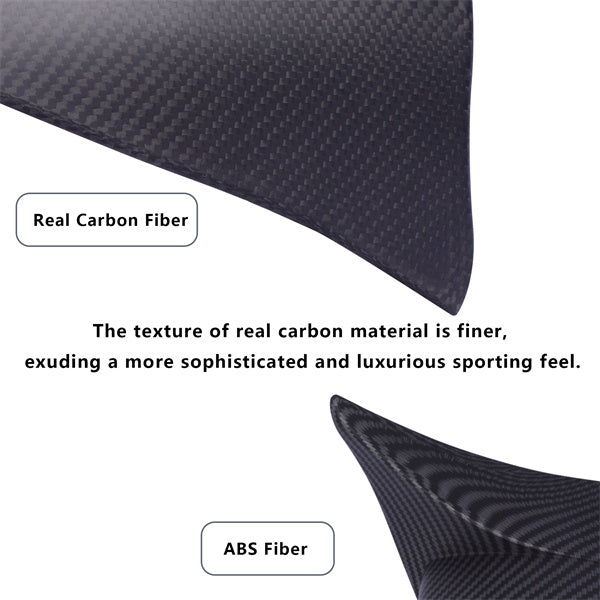

Texture: Real Carbon Fiber exhibits a unique surface texture, often described as a grid or fabric-like pattern. This distinctive appearance is one of the reasons why real carbon fiber products are highly popular, adding a sense of elegance and luxury.

Aesthetics: Real carbon fiber patterns include twill, straight weave, and forged; surfaces can have a glossy or matte finish.

Why choose Teslaunch's Tesla real carbon automotive accessories?

Raw Materials: We use Japan's Toray 3K carbon fabric, known for its high strength and fine texture. Toray's carbon fiber products find extensive applications in sectors such as aerospace, automotive, and sports equipment. The company has consistently been at the forefront of developing high-performance carbon fibers, providing lightweight and high-strength solutions for various applications. The manufacturing of carbon fiber products typically involves precision processes and advanced technological equipment, and Toray is renowned in the industry for its cutting-edge technology and quality.

Craftsmanship: Employing a vacuum high-pressure dry forging process, our products are lighter and have a more lustrous surface compared to traditional wet manufacturing.

Upgraded Your Model S/X with Real Carbon Fiber

Shop real carbon fiber accessories for Model 3/Y: https://bit.ly/48FKaBm